"Our community partner was so supportive; they challenged us to do our best work."

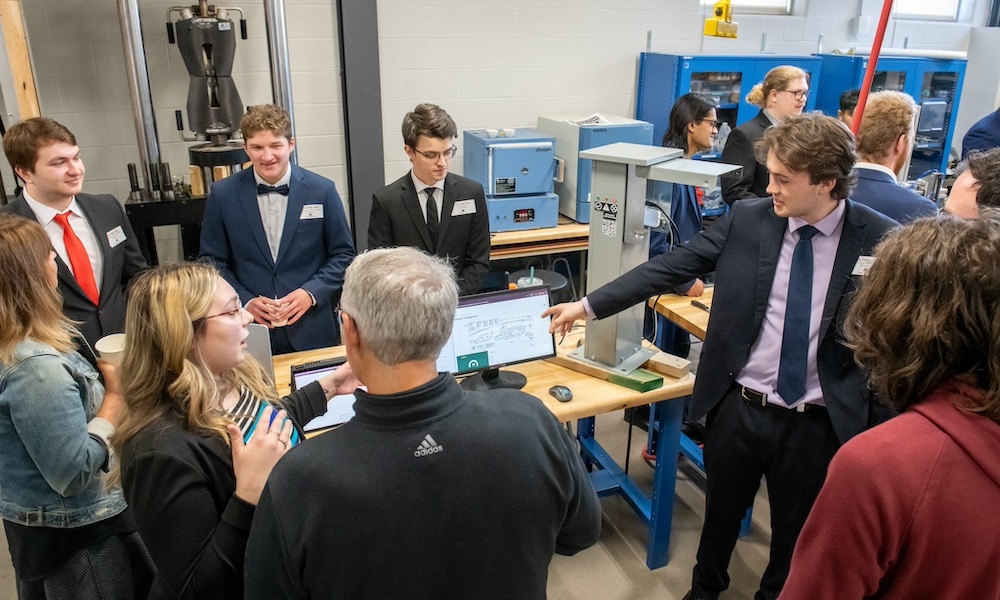

In the second, third, and fourth years of UPEI's Bachelor of Sustainable Design Engineering program, students form small groups to participate in a year-long design and implementation project with a corporate or community partner. Described as "an opportunity for students to act as engineering consultants for a company or organization, where teams of students team solve an actual technical challenge from the partner's operation", the design clinic program is a truly hands-on, real-world learning experience.

Sustainable Design Engineering student team members Lauren Daigle, Christian D'Entremont, Ben MacEachern, Josh McIsaac, and Owen Stewart worked with Parks Canada to design of a user-friendly display for the electric pedestals at campsites to inform campers of their energy consumption.

Tell me a little about your project.

Lauren: "We're working with Parks Canada to design an energy monitoring system. Parks Canada has seen increased energy usage at campground within the PEI National Park, and circuit breakers trip frequently. Each time happens, a staff member has to manually reset the breakers. The pedestal has a user system and a staff system: the user system has green, yellow, and red lights to show the level of current they draw, and a QR code with instructions on how to reset a tripped breaker. The staff system is a comprehensive dashboard that reads all the data from the pedestal and sends it to a computer in the campground kiosk, letting staff know first if there's a usage issue at a campsite."

Ben: "We also designed an app that takes the reports from the dashboard to present a graph to visitors—it tells them how much electricity they used during their stay, how many trees need to be planted to offset their electricity use, and how much that costs. We're hoping by presenting those costs, visitors may choose to plant as many trees as would offset the energy use."

How did you choose this project, and how did you work together as a team?

Lauren: "At the beginning of the year, we receive a list pf potential projects, and each individual ranks them according to their interests. I ranked this project first; actually, I think we all did! So I'm glad I was part of it."

Owen: "I think we're all interested in renewable energy and this project aligns with that interest."

What kinds of challenges did you face during the project?

Lauren: "We wanted to use Wi-Fi to transmit and receive data with 130 pedestals at Stanhope Campground, but the current wireless infrastructure wouldn't allow it. We tried Bluetooth and cellular networks, but Bluetooth's range was too short and cellular was too expensive. We ended up using a long-range radio frequency. We had a lot of help from our technicians here, Anthony Van Beek especially, and he's a very capable electrician but we learned a lot about it."

Josh: "When we started with our partner in first semester, we thought we may be able to use their main circuit breaker for all the pedestals at the campground, and thought we could put existing energy monitoring devices on each breaker panel. But, we discovered we could measure only short loops, which isn't what our client was hoping for. We had to completely reset and restart our project."

Lauren: "It was really stressful."

Ben: "It happened around the end of November, and we had to make a presentation at the start of December. We had about a week to redesign and come up with a brand new solution. We pretty much pivoted to a completely new design."

Owen: "The software was kind of hard to do, but we designed and straight coded the app. We didn't even know we needed the app until that point; just kind of like noticed we needed it. That was one of the things that wasn't part of the project scope we added."

Lauren: "It's just part of the design process we followed. We do that with every project: fail a lot and just keep iterating. And we very much did that. I think that we followed the design process well, and we kept building upon our project to make it better. This prototype was pretty much done a month ago, but since then we've been adding things, making it look nicer and just polishing the final product, which I think is really important for designs. The end result in April was not what I was expecting when I signed on for this project in September. But I love it, I'm proud of it."

What did you particularly enjoy about the project work?

Christian: "I think my favourite part was the customization, and how we made everything "ours" with the final prototype. We were able to build custom graphs and a map to show each campsite number, and the load at each site indicated by the same colour as the light on the pedestal."

Lauren: "I really liked was the fact that the scope of our project actually changed quite a bit over the year. Originally, the pedestal was designed to have a display screen on it, so you could read how much energy you were using in real time, but most people don't know what the electrical terms and units mean. Screens were also too expensive to implement across every pedestal in the campground, and they're not sustainable as they may get damaged or stolen. Talking with Parks Canada to adjust the scope was easy, they were very understanding."

Owen: "We had a really good community partner in Parks Canada. They, were always trying to help us out, there to help us. And I really enjoyed the technical aspects of the project, trying to get all the components and systems to work together in a final design."

Ben: "What I really liked about the project is the hands-on experience I got working with the electrical equipment, it gave me a better understanding of how the pedestal fully works, and I enjoyed the fact that our community partner was so supportive and challenged us to do our best work. They were involved from the start, and by asking for additional features they pushed us to see what we could do."

Josh: "Yeah, doing the hands-on work and solving the problems as they came up, and designing the user interface and coding was really challenging. And calculating how many trees needed to be planted per kilowatt hour of electricity use."

Why are clinic projects in Engineering at UPEI so unique?

Lauren: "We have clinic projects every year, which is unique compared to other programs, especially other engineering programs in Atlantic Canada. A lot of their projects are capstone projects in their fourth year. And I have friends in other engineering programs at other universities, and their projects are very focused on electrical engineering, or mechanical engineering. All of our clinic projects incorporate electrical or mechanical engineering concepts, but all of them have an incorporated sustainable design component."

Ben: "We were able to use a lot of in-house expertise and products, like the relays and the wiring components. Students have access to any tool you can imagine. And then if you need anything electrical, you can go to the electronics lab. Our technicians can help you in the Mechatronics lab."

Christian: "It's like $240 per pedestal for the entire working unit. Our full prototype cost was significantly under budget, I think we spent only $400 on the entire product."